Upgrade 120v Electrical System

A number of upgrades are recommended for the boat's 120v electrical system. It is intended that this task will be completed over Winter 2008/2009.

Contents

Status

As of June 1, 2009

As of June 1, 2009, the 30-amp shore power connector (on deck is connected to the new electrical panel. The shore power ground connection is connected through a galvanic isolator. The receptacles and water heater are connected to the panel. The battery charger is NOT yet connected. The ground connection from the panel is NOT yet connected to ships ground. Do NOT use the 120v system yet.

As of Nov 21 2008

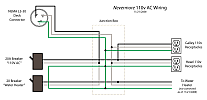

As of Nov 21 2008, the 30-amp shore power connector (NEMA type L5-30) on deck is connected to the onboard 120v receptacles through a switch/circuit-breaker mounted on the aft side of the emergency equipment cabinet. The Tartan documentation lists this switch as a 20-amp breaker. The hot water heater is not connected to AC power and the old batter charger has been removed.

Issues

Some of the issues with the current 120v system include:

- No master double-pole breaker for 120v system.

- No galvanic isolation from shore power

- Existing breakers are old and of unknown reliability

- 120v receptacles are not GFCI

- Water heater is not connected

- Battery charger is not installed

- No status indication of ground fault or reverse polarity on shore power.

Recommendations

New Breaker Panel

The existing breaker panel should be replaced. The new panel should include:

- A 30-amp double-pole switched master breaker that interrupts both "line" and "neutral" connections from shore power.

- Reverse-polarity indicators to indicate if "line" and "neutral" are interchanged on the incoming shore power voltage.

- At least three sub breakers that are fed from the 30-amp master breaker:

- 120v receptacles (15 amp)

- Hot water heater (15 amp)

- Battery charger (10 amp)

- Lights and/or a meter to indicate if voltage is present.

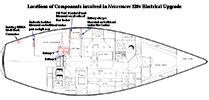

The existing breaker switches for the outlets and hot water heater will be removed. The new breaker panel will fit nicely there. It is a good location because it is physically close to the shore power receptacle, the batteries, and the engine. The only downside is that it will use up a few inches of space inside the emergency equipment cabinet. That cabinet may be too small for emergency equipment anyway, so location of emergency gear may need to be moved.

Galvanic Isolator

A galvanic isolator should be installed between the ground lug on the shore power connector and the boat's 120v ground system. This isolator should be located as closely as possible to the shore power inlet connector. It is proposed that the isolator be placed on the aft-side of the bulkhead underneath the port-side cockpit seat. This is directly underneath the cockpit instruments, and directly aft of the port-side berth.

It is recommended that the current rating of the isolator be at least 120% of the breaker rating of the shore power that is feeding the system.

GFCI Outlets

Existing 120v AC receptacles above the galley sink and in the head should be replaced with GFCI outlets. If there is potential for water to be splashed on the outlet (such as the one in the head), the outlet should be equiped with hinged covers.

A third set of GFCI receptacles could also possibly be located near the nav station. This way, people can plug in laptops, or other personal gear, and use them at the nav table, without runnning a power cord across the companionway steps and over the sink.

AC/DC Ground Connection

A heavy (6 AWG) wire should be run from the 120v ground system, preferreably at the main breaker, directly to the engine "negative terminal".

Water Heater

The water heater needs to be connected to AC power and tested. Note that it should NOT be powered on, unless it is completely filled with water (wait until spring to test).

Junction Box

Junction boxes in marine 120v systems are not recommended. If possible, the junction box just forward of the nav station (in the PFD cabinet), should be eliminated and all 120v wiring should run directly to the new breaker panel.

Battery Charger

The old battery charger was in a compartment forward of the nav station and aft of the port water tank. This compartment is currently being used as stowage for several large objects, for which there are no other good stowage locations. Perhaps a better location for the battery charger would be in the empty space underneath the nav station table. This is conveniently close to the batteries, it is well-ventilated and it is out of the way.

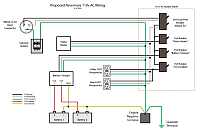

Upgrade Plan A

- The existing NEMA L5-30 deck connector will remain in place.

- A Guest 50/60 Amp Galvanic Isolator will be mounted on aft-facing side of the bulkhead underneath the port cockpit seat.

- Green 12 AWG wire will be run from the ground terminal on the deck connector to the isolator four feet away.

- Green/yellow striped 12 AWG wire will be run from the isolator back to the deck connector and spliced onto the ground wire of the existing electrical cable that leads from the deck connector.

- The existing 120v panel on the aft side of the emergency equipment locker will be removed and a new Paneltronics 9972313B 3-Position Panel will be mounted in its place.

- The existing electrical cable from the deck connector will be connected to the 2-pole master breaker.

- The existing electrical cables to the 120v receptacles will be connected to the first breaker on the panel.

- The existing eletrical cable that leads to the hot water heater will be connected to the second breaker. The other end of this cable will be connected to the water heater.

- A Xantrex Truecharge 10TB Battery Charger will be mounted on the aft-facing bulkhead under the nav station.

- A new 3-14 AWG 120v electrical cable will be connected to the third breaker and will be connected to the 120v AC connectors on the battery charger.

- Two new 2-12 AWG cables will be run the 6 feet from the battery charger to batteries #1 and #2.

- Battery #3 will be removed and recycled.

- The existing 120v receptacles in the head and the galley will be replaced with new GFCI receptacles.

- Another new GFCI receptacle will be mounted next to the 12v socket directly above the emergency equipment locker (behind the FM radio).

- A heavy (6 AWG) green wire will be run from the 120v breaker panel directly to the engine "negative terminal".

- The junction box in the PFD cabinet above the port bench will be removed.

Cost

| Galvanic Isolator | $189.99 |

| Master AC Panel | $151.99 |

| 3 GFCI Outlets | $24.00 |

| Wire | $30.00 |

| Total | $395.98 |