Difference between revisions of "X-Dimension systems"

| Line 162: | Line 162: | ||

== Power Train == | == Power Train == | ||

| − | + | The "Engine & Drive" section, pp. 5-6, of the previous owner's [http://sailing.mit.edu/wikiupload/3/31/X_Dimension_Manual_of_Useful_Information.pdf "Useful Info"] has some data about the power train and how to operate it. | |

| − | + | The Perkins engine SHOP and PARTS manuals are available only as web copies as listed in the [http://sailing.mit.edu/mediawiki/index.php/Xdim_documents | documents list]. As of now (30Aug11) we are verifying their dates when printed relative to our engine's age, and looking for a complete parts manual. | |

| − | + | === Engine === | |

| − | + | * Perkins 4-108 diesel (4-cyl, 50-hp), new to X-Dimension in 1989 | |

| − | + | * Serial # ED70058U630095P (mfg 1987)<br>(ED=4.108; 70058=parts list Nr; U=mfg UK; 630095=engine S/N; P=1987) | |

| − | + | ||

| − | + | === Transmission === | |

| − | + | ||

| − | + | * Newage gearbox, approx 2001 | |

| + | * PRM DELTA Gearbox; P/N=DELTA20, Serial #=C913041, Work Order #=R00629 (ref. loose packing sticker aboard) | ||

| + | * Manual: [[Media:x_dim-PRM_Delta_gearbox-shop_manual_1996.pdf | PRM DELTA MARINE GEARBOX Workshop Manual]] | ||

=== Coupler, Stuffing Box and Cutlass Bearing === | === Coupler, Stuffing Box and Cutlass Bearing === | ||

| Line 179: | Line 181: | ||

=== Propeller === | === Propeller === | ||

| − | + | * Max-Prop feathering 2-blade propeller, unknown size/pitch/model#/etc | |

| − | + | ||

| − | + | ||

| − | + | A pamphlet found in Sep 2011 indicates a 3-blade prop, but the boat has a 2-blade prop installed. | |

| − | + | === Muffler === | |

| − | + | ||

| − | + | * Vernalift (unidentified model & mfgr) Thomasville, GA | |

| − | + | ||

| − | + | === Fuel System === | |

| − | + | ||

| − | + | * Emergency fuel cut-off: TBD | |

| − | + | * Filler deck fixture located port toe rail | |

| − | + | * Filler filtering: none | |

| − | + | * Primary fuel filter / water separator : on stbd lazarette bulkhead; Racor 500 FG S/S | |

| − | + | * Fuel inlet screen: TBD | |

| − | + | * Primary fuel lift pump: TBD | |

| + | * Fuel Tank: | ||

| + | ** Capacity: 40-gal, giving approx 288 miles @ 2000 RPM using 0.9 gal/hour at 6.5 kt | ||

| + | ** Material/when Installed/Replaced: TBD | ||

| + | * Fuel gauges: | ||

| + | ** There is a mechanical fuel gauge located under the port main saloon bunk cushion. It is quite accurate when the boat is level. | ||

| + | ** The electrical fuel gauge(s) are not operative as of May 2012. | ||

== Steering == | == Steering == | ||

| Line 222: | Line 228: | ||

== Bilge Pumps == | == Bilge Pumps == | ||

| − | + | There are two electric bilge pumps and two manual bilge pumps. The primary electric is a diaphram pump located in the cabinet beneath the nav station. The secondary is a submersible located in the center portion of the bilge well. Float switches for these pumps are located in the bilge well. The primary manual is located in the port bulkhead of the cockpit just forward of the helm. The secondary manual is located under the floorboards of the foul weather gear locker. It can be operated without removing the floorboards. | |

| + | Individual auto-manual-off controls for each electric pump are located port of the nav station. These are energized by the always-on bilge pumps breaker in the main breaker panel. | ||

| − | + | All bilge hoses exit the boat starboard of center at the transom. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| + | === Primary Electric === | ||

| − | * | + | * Jabsco Model 34600-Series Electric Diaphragm Bilge Pump |

| − | + | * Rule-a-Matic float switch | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | === Secondary Electric === | |

| − | + | ||

| − | + | * Rule 1500 GPH submersible bilge pump | |

| − | + | * Rule-a-Matic float switch | |

| − | + | ||

| − | + | === Primary Manual === | |

| − | + | ||

| − | + | * Whale Gusher 10 | |

| − | + | * repair kit is West Marine part # 255658 OR 135038 | |

| − | + | ||

| − | * | + | === Secondary Manual === |

| − | * | + | |

| − | * | + | * Whale |

| − | * | + | * repair kit is |

| − | * | + | |

| − | + | === Strum Box === | |

| − | + | ||

| + | * strum boxes are 1 1/2" West Marine part # 100729, Whale mfg. part # SB5865 | ||

| + | |||

| + | See the previous owner's [http://sailing.mit.edu/wikiupload/3/31/X_Dimension_Manual_of_Useful_Information.pdf Useful Info] writeup, page 7, section headed "Bilge Pumps" for the previous configuration. | ||

== Head == | == Head == | ||

| + | |||

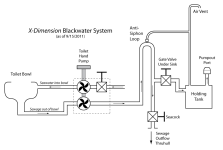

[[IMAGE:x-dimension_blackwater.png|thumb=x-dimension_blackwater_tn.png|right|X Dimension Blackwater System]] | [[IMAGE:x-dimension_blackwater.png|thumb=x-dimension_blackwater_tn.png|right|X Dimension Blackwater System]] | ||

| − | The head is a | + | The head is a hand-operated marine toilet unit connected to a 25 gallon expanding holding tank. The output from the toilet goes into the holding tank. From the holding tank there are two hoses, one to a pump-out fitting on the deck, the other to a thru-hull under the forward cabin sink. |

| + | |||

| + | The forward facing panel beneath the sink in the forward cabin can be removed for access to the thru-hull valve. | ||

| + | |||

| + | The seawater in thru-hull is located port of center under the main cabin floorboards, just aft of the mast. A small mesh strainer is located inline soon after the thru-hull valve. | ||

| − | The | + | The toilet is Jabsco model 29090-2000 (compact bowl & seat). |

| − | + | '''Previous Configuration:''' The head is a standard Jabsco hand-operated marine toilet unit connected to a very small (~5 gallon) holding tank. The output of the toilet routes through an anti-siphon loop directly to a through-hull valve. The holding tank seems to have been added as a retro-fit. A T-fitting is inline above the through-hull which routes the waste through a gate valve and then into the holding tank. By lifting the teak lid next to the sink in the forward cabin vanity, one can see the hose and valve to deflect sewage into the small holding tank or overboard. The coupling for pump out is located near the valve assembly. Pump out stations have several coupling styles and can match as necessary. At the present time (09/13/2011), the head is configured to deflect sewage overboard; the gate valve to the holding tank is stuck closed and the seacock is stuck open. The head is currently placarded "Head Inoperative Do Not Use" | |

== Refrigerator / Ice Box == | == Refrigerator / Ice Box == | ||

Revision as of 08:49, 18 May 2012

This is an exhaustive list of X-Dimension's various subsystems.

Contents

Specifications

Specifications provided by David Collins:

Length Over All (LOA): 43.4 ft

Waterline Length: 35.9 ft

Maximum Beam: 13.0 ft

Draft: 7.75 ft (7 ft 9 in)

(Note: original draft was 7.50 ft

but keel was modified by original owner)

Displacement: 22,000 lbs

PHRF/NE Rating: 72 base;

as sailed 2011: 87 racing, 90 cruising

Powerplant: Perkins 4-108 50hp (new in 1989)

Mast and rig: Sparcraft tapered 2-spreader /

discontinuous rod (new in 2007)

Fuel Capacity: 40 gal

Water Capacity: 80 gal

C&C Custom 43 specifications, but actual dimensions may differ. For example, mast was replaced in 2007 and keel was modified by previous owner, Blair Vedder. The values below should not be used without independent verification.

Hull Type: Fin Keel

Rig Type: Masthead Sloop

LOA: 43.33' / 13.21m

LWL: 35.00' / 10.67m

Beam: 12.83' / 3.91m

Listed SA: 901 ft2 / 83.7 m2

Draft: 7.00' / 2.34 m

Displacement: 21314 lbs./ 9668 kgs.

Ballast: 9980 lbs. / 4527 kgs.

Designer: Cuthbertson & Cassian

Builder: C&C Yachts (CAN)

Construct.: FG

First Built: 1971

Last Built:

# Built:

RIG DIMENSIONS

I: 56.00' / 17.07m J: 18.80' / 5.73m

P: 50.00' / 15.24m E: 15.00' / 4.57m

PY: EY:

SPL: ISP:

SA(Fore): 526.40 ft2 / 48.90 m2

SA(Main): 375.00 ft2 / 34.84 m2

Total SA: 901.40 ft2 / 83.74 m2

SA/Disp: 18.83

Est. Forestay Len.: 59.07' / 18.00m

Rigging

Standing Rigging

Mast

- Total length of mast: 63' 11.5"

- Height of mast above deck: 57' 0.5"

- Height of lower spreader above deck: 22' 0.5"

- Height of upper spreader above deck: 41' 2.75"

- Height of foredeck light above deck: 25'

- Distance from base of mast to deck: 6' 11"

- Distance from base of mast to foredeck light: 31' 11"

Backstay Adjuster

Sailtec Integral Backstay Adjuster (Model 10SI), brochure on web (no operating instructions)

When sailing upwind, the backstay should be adjusted so that the piston is approximately 2 inches from the white gauge on the shaft (2" minimum). Cross check the headstay sag. In moderate winds, the headstay should have very little sag.

Sails Kept on the Boat

General: The [Owners "Helpful Hints"] has various advice in the pages 4-5 "Sail Control" section.

Mainsail

Lazy Jack Installation Manual (no title) for the E-Z-JAX mainsail furling system. Page 4 of this manual gives operating instructions; the rest of the manual is e.g. parts identification and installation instructions.

The mainsail is normally kept furled on the boom with a sail cover.

Headsails

The #3 Genoa (approximately 135%) is normally kept on the roller furler.

The #1 Genoa is a carbon-reinforced racing sail that is normally kept in the forward v-berth and used for racing.

Spinnaker

The Asymmetric Spinnaker is normally kept in a spinnaker bag in the forward v-berth. It is equipped with a snuffer.

Note: Spinnaker pole storage on toe-rail requires periodic checking even on sails not using spinnaker, because of its current (Sep 2011) shortened length (see Ongoing Problems list.)

Current Inventory of Sails at the Pavilion (as of 02/09/2012)

Mainsails

Working mainsail (tied with sail ties, but not in a sail bag)

Old mainsail (in blue North Sails bag)

Jibs and Genoas

Genoa #1 (a carbon-reinforced racing sail, tied with sail ties but not in a sail bag)

Genoa #2 (in brown Sperry Sails bag labeled "new #3 Genoa") (note: This is an estimate based on the fact that the #3 Genoa is normally kept on the furler and accounted for below).

Genoa #3 (tied with sail ties, but not in a sail bag)

Storm Jib (in white sail bag with faded lettering)

Asymmetric Spinnaker

Working Asymmetric Spinnaker (in blue spinnaker bag, equipped with a snuffer)

Symmetric Spinnakers

0.5 oz Tri Radial Symmetric Spinnaker (in North Sails blue bag dated 1979)

0.75 oz Symmetric Spinnaker (in North Sails blue bag)

0.75 oz Symmetric Spinnaker (in yellow UK Sailmakers bag)

1.5 oz Star Cut Symmetric Spinnaker (in yellow sail bag)

1.5 oz Tri Radial Symmetric Spinnaker (in blue sail bag)

Deck

Winches

When delivered to MIT in August 2011, X-Dimension sported 15 winches. After winter refurb January 2012, X-Dimension has 13 winches. From bow to stern they include:

fore mast port - barient 22 fore mast stbd - barient 20 mast port - barient 28 aft mast port - barient 22 aft mast stbd - barient 22 companionway port - barient 22 companionway stbd - meissner 27 traveler port - barient 10p traveler stbd - barient 10 fore cockpit - 2x barent 32 aft cockpit - 2x barent 35

Traveler

The traveler is built of Harken "big boat" and HL (high load). The purchase is 4:1.

- track: 5 foot long Harken 32mm

- end controls: Harken 5170 with cam cleat

- car: Harken T3242B.HL

Machinery

Power Train

The "Engine & Drive" section, pp. 5-6, of the previous owner's "Useful Info" has some data about the power train and how to operate it.

The Perkins engine SHOP and PARTS manuals are available only as web copies as listed in the | documents list. As of now (30Aug11) we are verifying their dates when printed relative to our engine's age, and looking for a complete parts manual.

Engine

- Perkins 4-108 diesel (4-cyl, 50-hp), new to X-Dimension in 1989

- Serial # ED70058U630095P (mfg 1987)

(ED=4.108; 70058=parts list Nr; U=mfg UK; 630095=engine S/N; P=1987)

Transmission

- Newage gearbox, approx 2001

- PRM DELTA Gearbox; P/N=DELTA20, Serial #=C913041, Work Order #=R00629 (ref. loose packing sticker aboard)

- Manual: PRM DELTA MARINE GEARBOX Workshop Manual

Coupler, Stuffing Box and Cutlass Bearing

Propeller

- Max-Prop feathering 2-blade propeller, unknown size/pitch/model#/etc

A pamphlet found in Sep 2011 indicates a 3-blade prop, but the boat has a 2-blade prop installed.

Muffler

- Vernalift (unidentified model & mfgr) Thomasville, GA

Fuel System

- Emergency fuel cut-off: TBD

- Filler deck fixture located port toe rail

- Filler filtering: none

- Primary fuel filter / water separator : on stbd lazarette bulkhead; Racor 500 FG S/S

- Fuel inlet screen: TBD

- Primary fuel lift pump: TBD

- Fuel Tank:

- Capacity: 40-gal, giving approx 288 miles @ 2000 RPM using 0.9 gal/hour at 6.5 kt

- Material/when Installed/Replaced: TBD

- Fuel gauges:

- There is a mechanical fuel gauge located under the port main saloon bunk cushion. It is quite accurate when the boat is level.

- The electrical fuel gauge(s) are not operative as of May 2012.

Steering

Thru-Hulls

As delivered to MIT in August 2011, X-Dimension had 11 thru-hulls.

After Winter 2011/2012 refurb, the thru-hulls are:

port v-berth 1.5" - blackwater out port forward of keel 1" - greywater out port mid-keel 0.75" - toilet in stbd mid-keel 0.75" - galley seawater port mid-keel 2" - speed impeller stbd mid-keel 2" - depth transceiver stbd aft of keel 1.5" - galley greywater out stbd mid cockpit ? - engine in stbd cockpit 1.5" - scuppers port cockpit 1.5" - scuppers port cockpit 1/2" at waterline - propane drain

Bilge Pumps

There are two electric bilge pumps and two manual bilge pumps. The primary electric is a diaphram pump located in the cabinet beneath the nav station. The secondary is a submersible located in the center portion of the bilge well. Float switches for these pumps are located in the bilge well. The primary manual is located in the port bulkhead of the cockpit just forward of the helm. The secondary manual is located under the floorboards of the foul weather gear locker. It can be operated without removing the floorboards.

Individual auto-manual-off controls for each electric pump are located port of the nav station. These are energized by the always-on bilge pumps breaker in the main breaker panel.

All bilge hoses exit the boat starboard of center at the transom.

Primary Electric

- Jabsco Model 34600-Series Electric Diaphragm Bilge Pump

- Rule-a-Matic float switch

Secondary Electric

- Rule 1500 GPH submersible bilge pump

- Rule-a-Matic float switch

Primary Manual

- Whale Gusher 10

- repair kit is West Marine part # 255658 OR 135038

Secondary Manual

- Whale

- repair kit is

Strum Box

- strum boxes are 1 1/2" West Marine part # 100729, Whale mfg. part # SB5865

See the previous owner's Useful Info writeup, page 7, section headed "Bilge Pumps" for the previous configuration.

Head

The head is a hand-operated marine toilet unit connected to a 25 gallon expanding holding tank. The output from the toilet goes into the holding tank. From the holding tank there are two hoses, one to a pump-out fitting on the deck, the other to a thru-hull under the forward cabin sink.

The forward facing panel beneath the sink in the forward cabin can be removed for access to the thru-hull valve.

The seawater in thru-hull is located port of center under the main cabin floorboards, just aft of the mast. A small mesh strainer is located inline soon after the thru-hull valve.

The toilet is Jabsco model 29090-2000 (compact bowl & seat).

Previous Configuration: The head is a standard Jabsco hand-operated marine toilet unit connected to a very small (~5 gallon) holding tank. The output of the toilet routes through an anti-siphon loop directly to a through-hull valve. The holding tank seems to have been added as a retro-fit. A T-fitting is inline above the through-hull which routes the waste through a gate valve and then into the holding tank. By lifting the teak lid next to the sink in the forward cabin vanity, one can see the hose and valve to deflect sewage into the small holding tank or overboard. The coupling for pump out is located near the valve assembly. Pump out stations have several coupling styles and can match as necessary. At the present time (09/13/2011), the head is configured to deflect sewage overboard; the gate valve to the holding tank is stuck closed and the seacock is stuck open. The head is currently placarded "Head Inoperative Do Not Use"

Refrigerator / Ice Box

- The refrigerator / ice box is located beneath the galley counter and can be accessed via two hinged hatches

- The refrigerator compressor runs on the 12V house battery and is located in the starboard lazarette outboard of the house battery box

- The switch for the refrigerator compressor is located in the panel above the galley sink

- The current draw of the refrigerator compressor is not known (as of 10/5/2011) so the refrigerator should only be run when the engine is charging the battery

- There is a shelf in the refrigerator compartment that will accommodate ice blocks

Stove

Freshwater

Electrical

12-volt

The best measure of the status of the house battery is to use the switch above the galley sink and toggle it to the right when the engine is stopped (i.e., not charging) and the battery switch is set to "House". There is a voltmeter near the switch that should indicate at about the red/green line. When the engine is running, the indicated voltage should ba approximately 14V. Note that the switch sometimes has a poor contact and needs to be jiggled a little to have it work. Note that the ammeter in the engine instrument cluster in the cockpit is not working.

110-volt

Anti-Electrolysis

There is an external zinc "guppy" that is deployed at the stern while the boat is on the mooring or at the dock.

Lightning Dissipation

Electronics

- TEMPORARY NOTE (02Sep11): The block tabulation of electronics documentation below will finally reside in the [Documents] section of this wiki.

- GPS: Garmin 541 Chartplotter GPS (mounted in cockpit port bulkhead)

QUESTION: is there an external GPS antenna mounted somewhere else?- Documents: GPSMAP 400/500 series:

- RADAR: JRC RADAR1000 (mounted display) (installed in cubby over Nav Station table)

- Instruction Manual (Installation and Operation)

- web: RADAR1000MKII First Ed Jan 2003, code no.7ZPRD0592

WARNING: MARK II is similar to x_Dimension's system; this manual may be helpful for general study, but NOT for use while operating aboard!

NOTE: both models 1000 and 1000MKII are obselete per JRC web with no parts support etc - h/c: JRC Instruction Manual - LCD RADAR RADAR1000, Aug 1998 KP (2000), code no.7ZPRD0407;

loose sheets: (2 ea) LADAR1000packing list, (2 ea) cutout templates

- web: RADAR1000MKII First Ed Jan 2003, code no.7ZPRD0592

- Instruction Manual (Installation and Operation)

- Magnetic COMPASS:

- Binnacle compass

- make and model: TBD

- seems to work generally (Sep11)

- has compass-light switch over sink

- status:

- has not been swung (Sep11)

- compass light hasn't been tested

- Starboard bulkhead compass

- Status: appears to be stuck? (Sep11)

- Binnacle compass

Sailing

- MULTI-DISPLAY: Garmin GMI 10 Sailing Instrument (mounted in port cockpit bulkhead)

(displays numeric, gauge, or graph formats via NMEA network)- Documents:

- Quick Start Manual: hardcopy aboard (Rev. A), and on web (Rev. B 2009) 20 pp)

- Operating Instructions: no hardcopy aboard, and none listed by Garmin

(However, note that Quick Start Manual has 16 pages of operating instructions.) - Installation Instructions: document aboard (Jan 2008), plus xerox single sheet p. 6,

Also document on web; we note that web lists two install manuals for different S/N ranges.

- Documents:

- WIND: Garmin GWS 10 (senses wind speed and angle)

- (probably no "Quick Start" or other ops manual, since e.g. GMI 10 must display wind data?)

- Installation Instructions

- web: Installation Guide for Garmin GWS 10 Wind Sensor [1] Mar 2009, p/n 190-00999-92_OB

- h/c: GWS 10 Installation Instructions (8 languages), Oct 2008, p/n 190-00999-92_0A

- WATER DEPTH: Thru-Hull Intelliducer (depth sounder)

- is there a display? guessing no dedicated display unit, probably works on GMI 10, maybe GPS?

'TODO:' survey boat for a dedicated display - Installation

- web: Thru-Hull Intelliducer Installation Instructions: [2]

installation instructions, Apr 2010, 190-00888-10 Rev. B - h/c: ... Intelliducer Installation Instructions, Mar 2008, 190-00888-01 Rev.B

- web: Thru-Hull Intelliducer Installation Instructions: [2]

- ??? QUESTION: is there a display for this instrument, or only?/mostly? GMI 10 ?

- is there a display? guessing no dedicated display unit, probably works on GMI 10, maybe GPS?

- INSTRUMENT DATA NETWORK:

- Garmin NMEA 2000 Interfacing (general information)

- web: Technical Reference for Garmin NMEA 2000 Products: [3]

pub Jul 2010, p/n 190-00891-00 Rev.C, 42 pp. - h/c: (extract of doc) w/o boilerplate; Jan 2008, 190-00891-00 Rev.A

- web: Technical Reference for Garmin NMEA 2000 Products: [3]

- AirBorn Electronics : RS232 Connections - tech info for wiring, 6 pp

AirBorn Electronics, http://www.airborn.com.au/rs232.html, printed Dec 2005

- Garmin NMEA 2000 Interfacing (general information)

Radios

- Fixed VHF: West Marine VHF500 DSC Fixed Mount Marine Radio

- web: Owners Manual for West Marine VHF500 Radio: Pub# UTZZ01920ZA(0) 72 pp, 8/16/05

NOTE that this PDF has printer's alignment marks and smallish text on 8.5x11 sheet. - h/c: TBF

- web: Owners Manual for West Marine VHF500 Radio: Pub# UTZZ01920ZA(0) 72 pp, 8/16/05

- Handheld VHF: West Marine VHF55 VHF Radio (hand-held)

- Owner's Manual, Revised 2/06, VHF 55 Product SKU 7642358

- AM/FM/CD: Receiver (fixed mount)

- web: Dual Electronics Corp. MXD25 AM/FM/CD Marine Receiver Installation/Owners Manual: [4]

- h/c: MXD26 Installation/Owner's Manual (operation), 2010, NSA0608-V01

Safety

- Fire Extinguishers:

- hand-held: approx 3 around cabins, probbly ABC, some new ones bought Aug-Sep11

TODO: enumerate and define positions in ship - fixed mount: large tank in port lazarette apparently to smother engine; appears to have heat-detector valve; unknown make or contents or capacity

TODO: study this unit & report here

- hand-held: approx 3 around cabins, probbly ABC, some new ones bought Aug-Sep11

PFDs

Throwables

- Throwable cushions

- aboard : 2, stored: _____where?_____TBD

- Lifesling man overboard recovery system

- parts to throw toward MOB in bag afixed to stern pulpit

- recovery tackle is stored _______where?___________TBD

- see web movie about usage and advantages

Jacklines & Harnesses

- Harnesses & tethers

- separate harnesss & tethers

- Integrated into PFD (harness & tether)